By: Scott Verdun, Echo Robotics

I have noticed recently whether while making customer calls or attending an industry function that I no longer belong to the younger demographic. This has been happening for a few years if I’m being honest and at this point, I likely have more in common with those who spend the winter in Florida than those looking for their first big career move; this isn’t a knock to those who winter in Florida, I spend a week there with my parents every winter and it’s fantastic!

After 20 years in any industry, I assume it’s common that as one makes the transition to one of the more experienced of a group the likely next step is to look back and reminisce about what has changed. While access to quality labor may be the biggest change in the past 20 years I’m going to focus on technology, some of which can likely alleviate some of the stresses caused by the labor market.

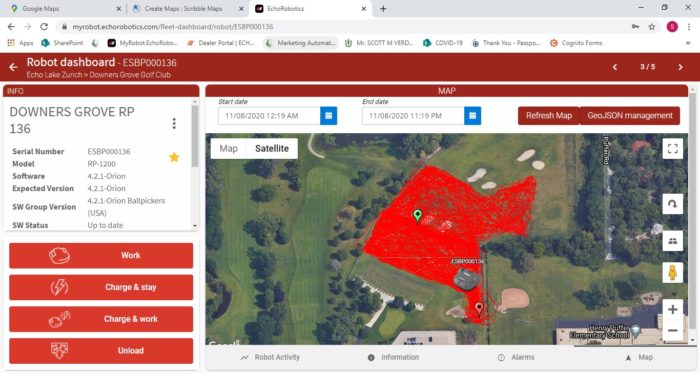

Meet ESBP000136, your new driving range picker and mower. It has three simple commands: work, charge and stay, or charge and work. By the way, it never oversleeps, calls in sick or needs to take a lunch break.

Looking back over the first half of my career, it can be remarkable how much the use of technology has grown the turf industry. When I first got out of college a cell phone ONLY made phone calls and not everyone had one. They also had real buttons, no data use ability, and if you wanted a picture you needed a real camera. Although digital had mostly overtaken film by then. Now the list of uses for a modern smart phone is virtually endless; program irrigation, monitoring weather, adjust your digital job board, correspond with anyone via dozens of different outlets, perhaps even tell your mowers to go to work.

Twenty years ago you were likely using a pocket knife or soil probe to test moisture content; now digital, Bluetooth connected moisture meters give volumetric moisture content and can create a map of dry or wet zones. Similar is the use of firmness meters in creating a surface that accepts an approach shot consistently across each putting surface. The ability to communicate has advanced tremendously from the printed newsletter to where most are at the very least using Email to using text blasts or social media to instantaneously communicate to their clientele. This list can go on forever to include a plethora of items and I’m sure you all have your own items to add. So, what’s next?

I think it’s safe to assume that environment, safety, and filling the labor gap will be at the forefront of a lot of product development. Autonomous equipment checks all of those boxes. In the early 2000’s at a Midwest Turf Clinic, it was predicted that in the not-too-distant future we would be programming our mower fleet to operate in the way we program irrigation. While we aren’t quite there yet in North America it has begun in Europe where autonomous mowing has been adopted on a much greater scale. So where does that leave us in North America? It leaves us 5-10 years behind Europe where autonomy here consists mostly of smaller units that can maintain a specified area, defined by a buried wire. These units require limited supervision, no fossil fuels, and virtually no noise pollution.

So, how does it work? Think Roomba for the grass (or to pick the range), however, instead of bouncing off the walls these units bounce off an Electro Magnetic (EW) signal transmitted via a buried wire two to three inches below the surface. Wires are placed to establish a boundary and after some programming and scheduling specific to each location a robot will safely and without human intervention go to work. Just like an employee these units are not perfect, they can get stuck on a mound of mulch and a hard enough bump in the ground could trigger a safety sensor; occasional supervision is required but can be done remotely via computer or an app on your phone. Much like current equipment, periodic inspection is recommended to check on blades, wheels or for basic cleaning.

You can track your new employee through an app on your phone/tablet or computer and see all the work that has been accomplished and what they’re up to at any moment.

Robots are able to work night and day, charge when necessary and in the case of a range picker it will dump the hopper of golf balls when full. In regards to driving range management and safety, a plastic covered robot is a much better target than a person protected by a net and in terms of mowing the range the robot won’t damage a golf ball if hypothetically a few got missed while being “clean picked” on Saturday evenings. The robot can eliminate the need to use labor to mow the range as well as alleviate a potential stress point between two key heads of their departments.

The left picture is the bottom of the mower deck with standard cutting heads installed. The middle has golf ball protection discs installed. The right picture is a close up of a cutting blade.

Mechanically robots are pretty simple and have a limited number of components when compared to traditional equipment. To start there is a computer which is where all initial set-up occurs. The robot is programmed to know which electro-magnetic channel is associated with each working zone, from here a strong signal can also be confirmed and adjusted if necessary. Other parameters are defined like height of cut, docking with a charger, and the scheduling of when to work.

All units are powered by two electric drive motors, one on each of the rear drive wheels and balance is provided by 4 caster wheels on the front of the unit. In addition, the range picker has an electric actuator which raises and lowers the hopper to dump the golf balls when full. The mower is equipped with either 3 or 5 cutting units depending on the size of the mower. Each cutting unit consists of 3 razor blades which operate with centrifugal force similar to a hover mower only smaller. There are also sonars, sensors across the front bumper, and lift sensors in each corner to ensure safe operation.

So, where is this going in the future?

Research and new technology are ongoing and while a fleet of autonomous fairway mowers is likely on the horizon, the next great advancements will likely be in efficiency. Random patterns will be replaced by back and forth or circle patterns. This will lead to opening up a greater total area covered while still utilizing the same amount of energy. As batteries become lighter and more efficient, mowers will be able to cover greater areas on less charges. Another addition will be the ability to set geo zones where higher concentration of golf balls will need to be picked more frequently or only pick balls on the target greens. This is likely where the next advancements in autonomous operations will be, but as you know technology moves fast. Will you see a neighborhood golf course with a fleet of autonomous fairways mowers in 2021?

Not likely, but it will be here soon and it will be a game changer for those willing to take the plunge.